At RDF we have many years of experience working with metal. We always deliver our solutions at the agreed time, price and always at the desired quality. With the newest technology and optimal production facilities our different kinds of machines are geared towards solving most tasks – the size and complexity of the item does not matter. This also goes for jobs within laser cutting. Laser cutting is a thermal cutting process that has the ability to cut many different materials. We are experts in laser cutting and perform laser cutting in metals like steel, stainless steel, brass, aluminum and copper.

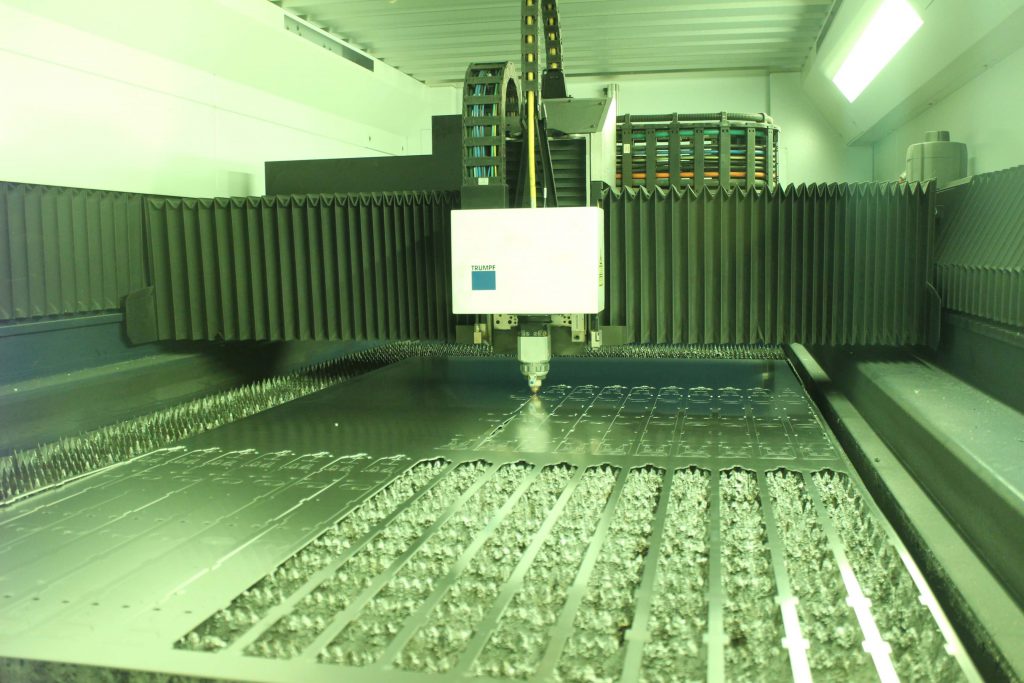

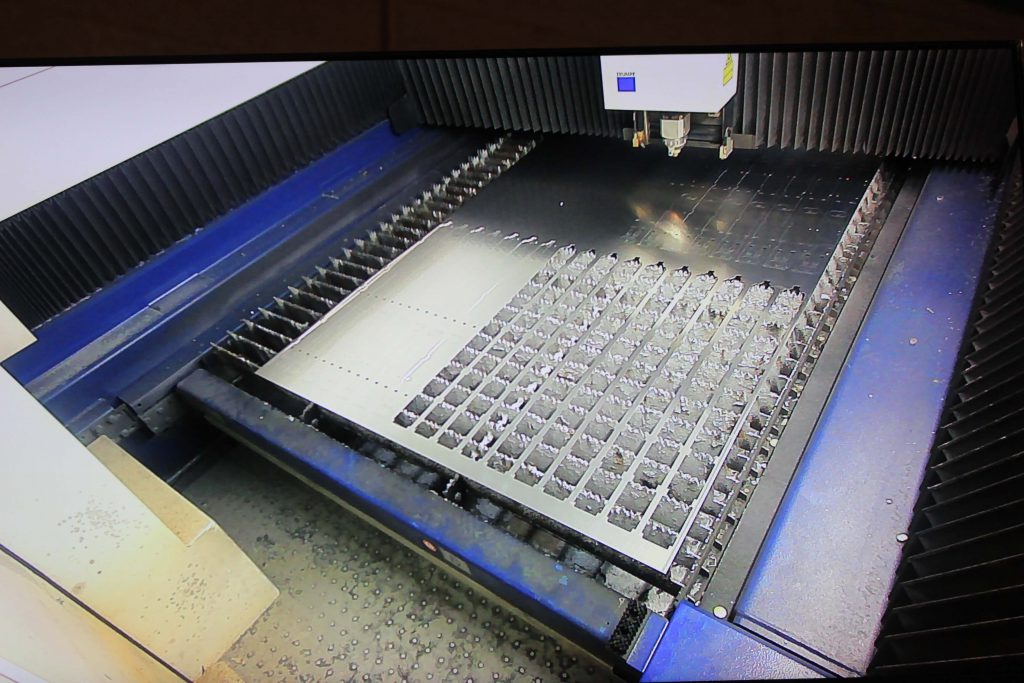

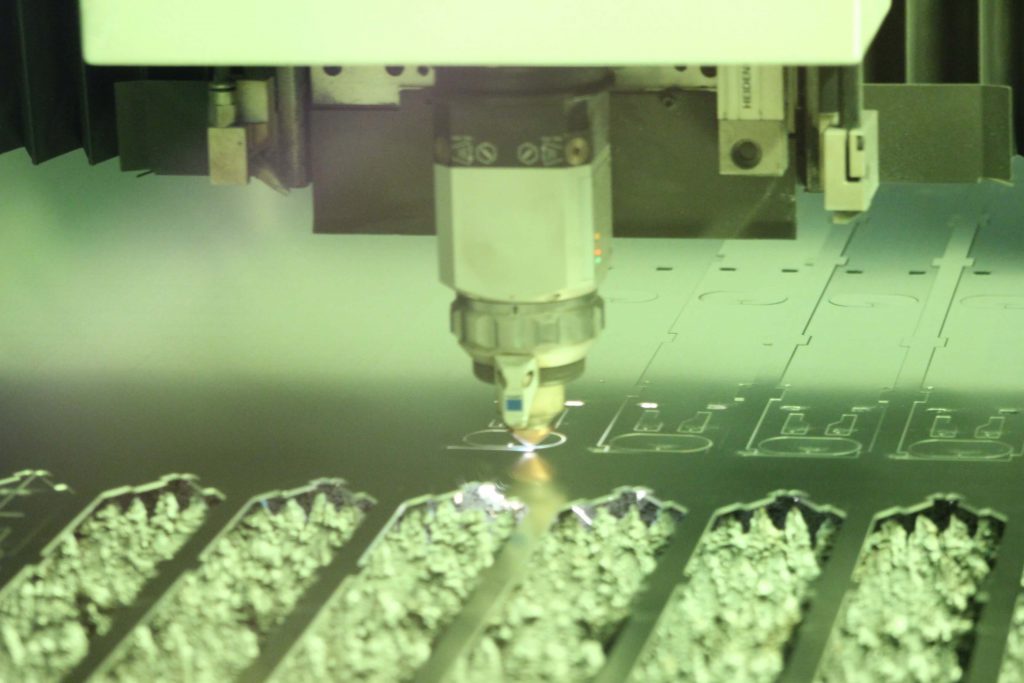

RDF offers laser cutting on our fully automatic CNC Trumf-plant with twin-tower. The laser cutter is a high speed fiber laser from Trumf that has the ability for water cooling in a thicker quality which enables cutting of small holes in relation to the thickness of the product. The plant is fully automated which means that it can generate raw materials from inventory systems and pre-cut items are picked from the partmaser as well.

Our laser cuts at a high speed with maximum accuracy. The laser cutter can cut up to one meter plate per second with less than 0.1 mm accuracy with sharp corners. We cut materials in plate sizes up to 1.500 x 3.000 mm with a thickness up to:

The laser cutter machines are highly automated with automatic handling of the plates as well as placement of the items on pallets. This contributes to a reduction in energy consumption in addition to a reduction in expenses. That also means that we ensure competitive prices on items and we take the environment into consideration at the same time.

The advantages of fiber laser cutting is:

We work with DWG files and DXF files which allows for high productivity, flexibility and accuracy which minimizes any finishing work. The minimal amount of heat exposure eliminates deformation and also provides the ability for the laser to cut complicated geometries. You can either hand over finished cutting files or you can create them in collaboration with our competent programmers. Do you have a sketch or an idea that you would like to make into reality? We offer product development and production which means that the time between idea and the finished product is limited.

Do you have any questions or are you interested in hearing about what we can offer within cutting with a laser cutter? You are more than welcome to contact us for a non-binding conversation about your possibilities at RDF.

| Cookie | Varighed | Beskrivelse |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |